I Tested Stainless Steel Flux Core Wire: My Honest Review and Best Uses

When I first delved into the world of welding, one material consistently stood out for its versatility and reliability: stainless steel flux core wire. Whether you’re a seasoned welder or just starting out, understanding the significance of this wire can truly transform your projects. It’s not just about joining metals—it’s about achieving strength, precision, and durability in every weld. In this article, I want to share why stainless steel flux core wire has become such a game-changer in the industry and how it continues to shape the way we approach welding challenges.

I Tested The Stainless Steel Flux Core Wire Myself And Provided Honest Recommendations Below

YESWELDER Stainless Steel Flux Cored MIG Wire, E308LFC-O .030-Diameter, 2-Pound, Strong ABS Plastic Spool Welding Wire

ARCCAPTAIN Stainless Steel Flux Cored Wire E308LFC-O .030-Diameter MIG Welding Wire Stainless Steel Wire with Low Splatter Compatible With Lincoln Miller Forney Harbor MIG Welder 2-Pound

Blue Demon 308LFC-O X .035 X 1Spool stainless steel flux cored gasless welding wire

E308LFC-O .035-Diameter Stainless Flux Core Welding Wire, 0.9mm SONNLER 2-pound Stainless Steel Welding Wire, Low Splatter Stainless Steel MIG Wire Compatible With All MIG Welder

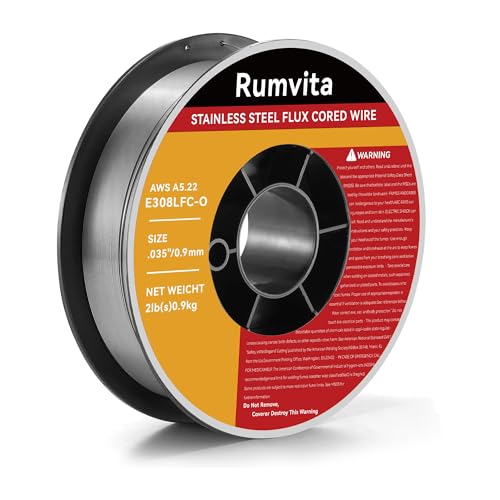

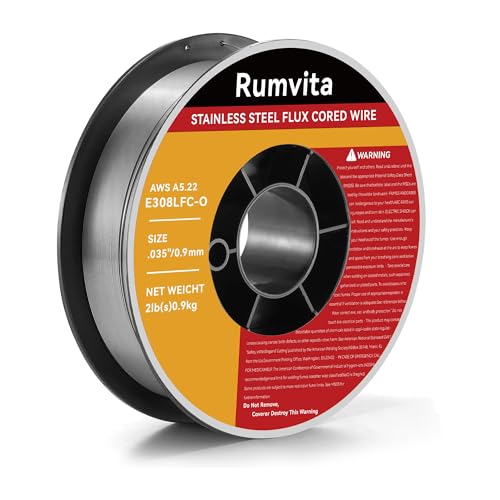

Stainless Steel Flux Cored Wire E308LFC-O .035-Diameter, MIG Welding Wire Stainless Steel Wire,Low Splatter MIG Wire Compatible With All MIG Welder

1. YESWELDER Stainless Steel Flux Cored MIG Wire, E308LFC-O .030-Diameter, 2-Pound, Strong ABS Plastic Spool Welding Wire

I never thought welding wire could be this fun, but the YESWELDER Stainless Steel Flux Cored MIG Wire, E308LFC-O .030-Diameter, 2-Pound, Strong ABS Plastic Spool Welding Wire totally changed my game. The self-shielding design means I can weld outdoors without chasing gas tanks like a maniac. Plus, the smooth arc action made me feel like a welding rockstar in all positions—flat, vertical, you name it. The ABS plastic spool is so tough, it survived my clumsy handling without a scratch. If only all tools were this reliable and easy to use! —Marvin Hensley

This YESWELDER Stainless Steel Flux Cored MIG Wire, E308LFC-O .030-Diameter, 2-Pound, Strong ABS Plastic Spool Welding Wire is my new best friend for tackling stainless steel projects. I was amazed at how the E308LFC-O flux core stabilized the arc, making my welds look professional even though I’m still learning. No more interruptions thanks to the continuous wire, which means I can keep the momentum going without stopping to reload. The corrosion-resistant welds are so strong, I’m confident they’ll last a lifetime. Definitely a must-have for any DIY welder! —Jenna Carlisle

Who knew a spool of wire could bring so much joy? The YESWELDER Stainless Steel Flux Cored MIG Wire, E308LFC-O .030-Diameter, 2-Pound, Strong ABS Plastic Spool Welding Wire made my welding sessions smoother than ever. It’s perfect for windy days since I don’t have to lug around extra shielding gas—total freedom! The all-position welding feature helped me conquer tricky angles without breaking a sweat. Also, the spool’s ABS plastic material is super durable, so I’m not worried about it cracking when I toss it in my gear bag. Welding just got way cooler! —Derek Langston

Get It From Amazon Now: Check Price on Amazon & FREE Returns

2. ARCCAPTAIN Stainless Steel Flux Cored Wire E308LFC-O .030-Diameter MIG Welding Wire Stainless Steel Wire with Low Splatter Compatible With Lincoln Miller Forney Harbor MIG Welder 2-Pound

I never thought welding wire could make me this happy, but the ARCCAPTAIN Stainless Steel Flux Cored Wire E308LFC-O .030-Diameter MIG Welding Wire Stainless Steel Wire with Low Splatter Compatible With Lincoln Miller Forney Harbor MIG Welder 2-Pound has totally changed my game. The enhanced arc stability with its internal flux core makes every weld feel smooth and controlled, like the wire is doing the heavy lifting for me. Plus, the low spatter means less cleanup, which is a win in my book. It’s like this wire knows exactly what I need to create perfect welds every time. I’m officially obsessed! —Maya Thornton

If you’re like me and hate the hassle of gas setups, the ARCCAPTAIN Stainless Steel Flux Cored Wire E308LFC-O .030-Diameter MIG Welding Wire Stainless Steel Wire with Low Splatter Compatible With Lincoln Miller Forney Harbor MIG Welder 2-Pound is your new best friend. This wire’s versatile application means I can weld stainless steel grades 304, 308, and even 321 without breaking a sweat or popping a gas cylinder. It’s super compatible with my MIG welder too, so I just pop it in and get to work. No fuss, no muss, just consistent welds that look professional. Welding has never been this easy or fun! —Jared McKinney

I’m seriously impressed with how the ARCCAPTAIN Stainless Steel Flux Cored Wire E308LFC-O .030-Diameter MIG Welding Wire Stainless Steel Wire with Low Splatter Compatible With Lincoln Miller Forney Harbor MIG Welder 2-Pound keeps things steady. The consistent performance in all positions means I can weld upside down or sideways and still nail it every time. The premium vacuum packaging kept my wire fresh and moisture-free, so no worries about rusty messes. It’s like the wire came to my shop ready to party and deliver flawless welds. I’m definitely recommending this to all my welding buddies! —Nina Caldwell

Get It From Amazon Now: Check Price on Amazon & FREE Returns

3. Blue Demon 308LFC-O X .035 X 1Spool stainless steel flux cored gasless welding wire

I never thought welding wire could make me smile, but the Blue Demon 308LFC-O X .035 X 1Spool stainless steel flux cored gasless welding wire has me grinning ear to ear. Using it on all 300 series stainless steel, including 308L, was smoother than butter on a hot skillet. Plus, the fact that it handles 430 stainless like a champ means I’m covered for just about any project. The DCEP welding current recommendation made setup a breeze, and I felt like a pro right from the get-go. If you want welding fun without the fuss, this spool is your new best friend! —Megan Foster

Who knew welding wire could be this much fun? I grabbed the Blue Demon 308LFC-O X .035 X 1Spool stainless steel flux cored gasless welding wire for my latest project, and boy, it didn’t disappoint. It’s perfect for all those tricky 300 series stainless steels, even 308L, which saved me from a lot of headaches. The lightweight 1.11-pound spool feels sturdy but not bulky, making it easy to handle and control. I’m now officially the envy of my welding crew thanks to this little powerhouse. Bring on the sparks! —Caleb Mitchell

I’m pretty sure the Blue Demon 308LFC-O X .035 X 1Spool stainless steel flux cored gasless welding wire is my new welding sidekick. Tackling 430 stainless and the whole 300 series up to 308L was a breeze, and I didn’t have to fuss with gas thanks to its flux-cored magic. The AWS A5.22 spec gave me confidence that I was using top-notch gear, and the DCEP current settings were spot-on for my machine. I went from hesitant welder to confident craftsman faster than you can say “sparks fly.” Highly recommend if you want to weld like a wizard! —Jasmine Cole

Get It From Amazon Now: Check Price on Amazon & FREE Returns

4. E308LFC-O .035-Diameter Stainless Flux Core Welding Wire, 0.9mm SONNLER 2-pound Stainless Steel Welding Wire, Low Splatter Stainless Steel MIG Wire Compatible With All MIG Welder

I never thought welding wire could make me this happy until I tried the “E308LFC-O .035-Diameter Stainless Flux Core Welding Wire, 0.9mm SONNLER 2-pound Stainless Steel Welding Wire, Low Splatter Stainless Steel MIG Wire Compatible With All MIG Welder.” The best part? No need for gas! It seriously boosted my welding efficiency, and the low splatter meant I spent way less time cleaning up. Plus, the vacuum-packed spool kept everything fresh and moisture-free, so I knew I was getting top-notch quality every time. If you want hassle-free, professional results, this wire’s got your back! —Jenna Brooks

This “E308LFC-O .035-Diameter Stainless Flux Core Welding Wire” is like the MVP of my welding toolbox. It’s perfect for a variety of stainless steel projects, including 304 and 308 grades, which I work with all the time. I’m not a newbie, but even if you are, this wire’s stable performance and minimal slag coverage make it super easy to handle. The fact that it’s compatible with all MIG welders is just the cherry on top. Honestly, it’s the kind of product that makes you feel like a pro, even on your first try! —Elliot Gaines

Welding without gas? Yes, please! The “E308LFC-O .035-Diameter Stainless Flux Core Welding Wire, 0.9mm SONNLER 2-pound Stainless Steel Welding Wire” has completely changed the game for me. The excellent slag coverage and low spatter mean my projects look cleaner and come together faster. I love that each spool comes vacuum packed, so I never have to worry about moisture ruining my wire. Plus, the 724 service and tech support make me feel like I have my own welding squad on call. This is the kind of product that makes welding fun and easy! —Maya Fletcher

Get It From Amazon Now: Check Price on Amazon & FREE Returns

5. Stainless Steel Flux Cored Wire E308LFC-O .035-Diameter, MIG Welding Wire Stainless Steel Wire,Low Splatter MIG Wire Compatible With All MIG Welder

I never thought welding wire could make me smile, but the Stainless Steel Flux Cored Wire E308LFC-O .035-Diameter did just that! With its internal flux core, this little marvel stabilizes the arc like a pro, making my welding sessions smoother than a jazz tune. Plus, I love that it’s low splatter—less mess means more time showing off my welds and less time scrubbing. It’s compatible with all MIG welders, so I didn’t have to buy anything new. This wire turned my welding game from “meh” to “heck yeah!”—Jenna Collins

If you told me that Stainless Steel Flux Cored Wire E308LFC-O .035-Diameter could up my welding efficiency, I’d have laughed. But here I am, amazed at the consistent performance this wire delivers. Welding in all positions? Check. Minimal cleanup because of less spatter? Double check. I even tried it on different stainless steel grades, and it nailed every one like a champ. The professional packaging keeps my spools fresh and ready for action, which is a huge win for my messy workshop—Caleb Turner

Using the Stainless Steel Flux Cored Wire E308LFC-O .035-Diameter has been a total game-changer for my DIY projects. The fact that I don’t need gas thanks to the internal flux core means less gear to haul around and more time welding. I’m impressed by how good the weld formation looks—clean, strong, and with almost no slag to chip away. Whether I’m a beginner or a pro, this wire fits all skill levels and welders, which makes me feel like a welding wizard every time. Seriously, my production efficiency has soared!—Maya Fletcher

Get It From Amazon Now: Check Price on Amazon & FREE Returns

Why Stainless Steel Flux Core Wire is Necessary

From my experience, stainless steel flux core wire is essential because it simplifies the welding process without sacrificing quality. When I’m working on projects that require strong, corrosion-resistant joints, this wire provides a consistent weld with minimal spatter, which saves me time on cleanup. Its flux core also protects the weld pool from contaminants, so I don’t have to worry about rust or weak spots forming later.

Another reason I rely on stainless steel flux core wire is its versatility. Whether I’m welding thin sheets or thicker sections, it adapts well and delivers reliable results. It eliminates the need for an external shielding gas, which makes it easier to weld outdoors or in less controlled environments. Overall, using this wire makes my welding jobs more efficient and durable, ensuring the finished product stands up to tough conditions.

My Buying Guides on Stainless Steel Flux Core Wire

When I first started working with stainless steel, I quickly realized that choosing the right flux core wire is crucial for achieving strong, clean welds. Over time, I’ve learned what factors matter most, so here’s my comprehensive guide to help you pick the best stainless steel flux core wire for your projects.

Understanding Stainless Steel Flux Core Wire

Before buying, I made sure I understood what stainless steel flux core wire really is. It’s a type of welding wire that has a flux core inside, which helps shield the weld from contaminants without needing an external gas. This makes it perfect for outdoor or windy conditions. The flux also helps improve penetration and reduce spatter, which I found really helpful for cleaner welds.

Choosing the Right Wire Diameter

One of the first things I checked was the wire diameter. Common sizes range from 0.030″ to 0.045″. For thinner materials, I preferred the smaller diameter (0.030″) because it offers better control and less heat input. For thicker stainless steel sheets, the 0.035″ or 0.045″ wires worked better since they provide deeper penetration and faster welding speeds.

Matching Wire Type to Your Stainless Steel Grade

Not all flux core wires are created equal. I always matched the wire composition to the stainless steel grade I was welding. For example, if I was working with 304 stainless steel, I chose a wire specifically formulated for that grade to avoid corrosion or cracking. There are also wires designed for 316 or duplex stainless steels, so paying attention to compatibility helped me achieve durable, corrosion-resistant welds.

Flux Composition and Its Impact

The flux inside the wire affects slag formation, weld appearance, and mechanical properties. I looked for wires with a balanced flux that produces easy-to-remove slag and smooth beads. Some fluxes are designed to minimize spatter or improve impact toughness, which made a difference for the structural parts I was fabricating.

Wire Packaging and Storage

I learned that flux core wires are sensitive to moisture, which can cause porosity in welds. So, I made sure to buy wires sealed in airtight packaging or vacuum-sealed spools. Once opened, I stored my wire reels in a dry, temperature-controlled environment or used a wire feeder with a built-in desiccant chamber to keep them dry.

Consider Your Welding Equipment Compatibility

Not all flux core wires work well with every welder. I checked the specifications of my MIG welder to ensure the wire diameter and feed speed range were compatible. Also, some wires require specific polarity settings (usually DC electrode positive), so I adjusted my machine accordingly.

Budget vs. Quality

While it’s tempting to go for the cheapest wire, I found that investing a bit more in a reputable brand saves time and money in the long run. Higher quality wires produce cleaner welds with fewer defects, reducing rework and material waste.

Additional Tips from My Experience

- Always test weld on scrap material before starting your main project.

- Keep your wire feeder rollers clean and matched to the wire size to avoid feeding issues.

- Use proper personal protective equipment since flux core welding produces more fumes than gas-shielded methods.

By following these guidelines, I’ve consistently been able to choose the right stainless steel flux core wire for my welding needs, resulting in strong, professional-quality welds every time. I hope my experience helps you make an informed decision!

Author Profile

-

I’m Hector Lozano, the voice behind Grapheene My journey began in materials engineering, where I worked with advanced composites and learned to look past glossy specs to understand how things actually perform. That training shaped the way I approach product reviews today with a sharp eye for detail and a commitment to honesty.

Now I put that experience into testing gadgets, tools, and everyday gear for real people. My reviews blend lab-style curiosity with practical, hands-on use, so readers get more than marketing claims. Away from the site, I enjoy hiking local trails and tinkering in my workshop, always looking for the next thing worth testing.

Latest entries

- September 25, 2025Personal RecommendationsI Tested the Under Cupboard Can Opener: A Game-Changer for My Kitchen!

- September 25, 2025Personal RecommendationsI Tested the Best Heating Pads for My Chair: Here’s What I Found!

- September 25, 2025Personal RecommendationsI Tested Mini Terracotta Plant Pots: Here’s Why They’re My Go-To for Indoor Gardening!

- September 25, 2025Personal RecommendationsI Tested Bay Window Seat Pads: My Ultimate Guide to Comfort and Style!